Case studies

View next case study

kSTEAM TURBINE APPLICATION - LEBANON

DSE LOAD SHARE CONTROLLERS USED IN STEAM TURBINE SYNCHRONISING APPLICATION

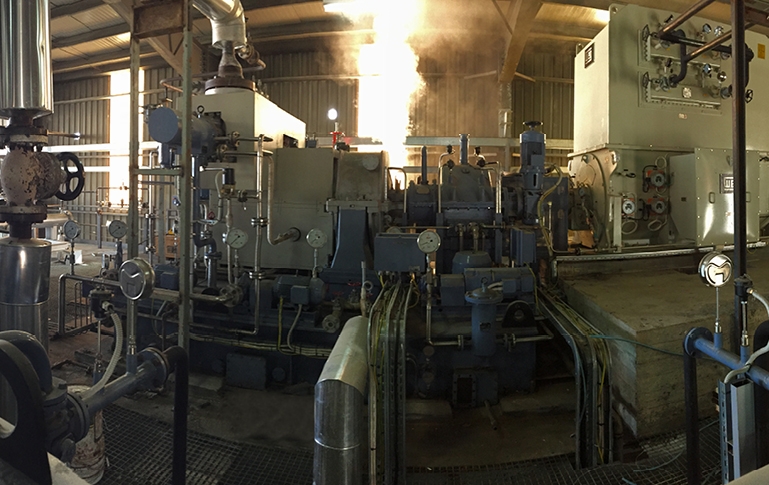

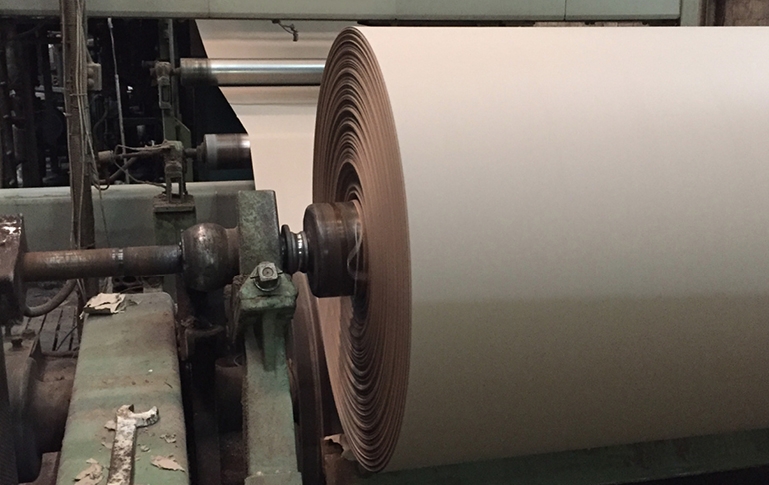

A cardboard manufacturing plant in Lebanon, which makes cardboard from 100% recycled paper and used cardboard, has found a sustainable way to run its operations off grid. Waste is brought to the site and first goes through a separation process to remove the useable paper and cardboard from the rest of the rubbish. This is then made into a pulp to be made into cardboard. The remaining waste is incinerated to generate steam used in the drying process while the remaining steam is used to power the steam turbine, providing AC power for the manufacturing process.

Five generators are installed to provide power for the turbine start-up and to support the application during times of high demand. All five generators are controlled by DSE8610’s and work automatically in synchronisation with each other, while a DSE8660 controls the paralleling & load sharing with the turbine. The drying part of the process has particularly high energy demands so it is a highly cost efficient solution to have generators on standby and only called into use when energy demands require it e.g. when the dryers are working or when volume is high.